Improve the manufacturability & value of your products.

Castings, patterns, molds, & industrial tooling engineered for value and quality:

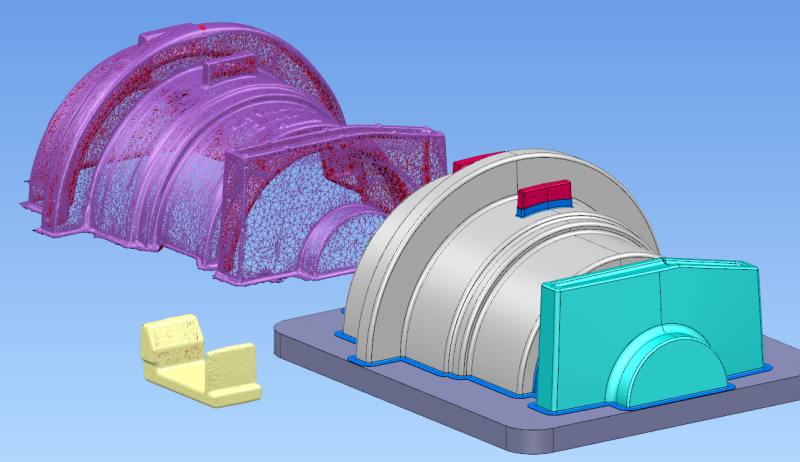

- 3D CAD Design of solid models from incomplete CAD data, scanned data, and 2D drawings.

- Reverse Engineering of existing products & tooling, including legacy and re-shored products.

- Design for Manufacturability & Value Engineering for improved performance and costs.

- Product Development & Optimization for quality and functional improvements.

- Cost Reduction of complex castings, cores, components, and tooling. Evaluate the utilization of 3D printed technology where economical.

Designs produced 100% complete with proper draft, parting lines, machine stock, etc.

30 years of experience designing and manufacturing complex 3D tooling:

- vertical and horizontal sand casting patterns: Disa, Sinto, Hunter, Osborne, etc.

- high-production core boxes: Laempe, Loramendi, B&P, Redford, Shalco, etc.

- aluminum permanent molds: tilt-pour, reverse-tilt, static

- compression and lay-up molds for plastics and composites.

- tooling projects with multi-directional draws, cores, slides, loose pieces

- trim dies, fixtures, material handling, core setters, etc.

Software: Solidworks, Autodesk Powershape.

Direct import most CAD file formats.

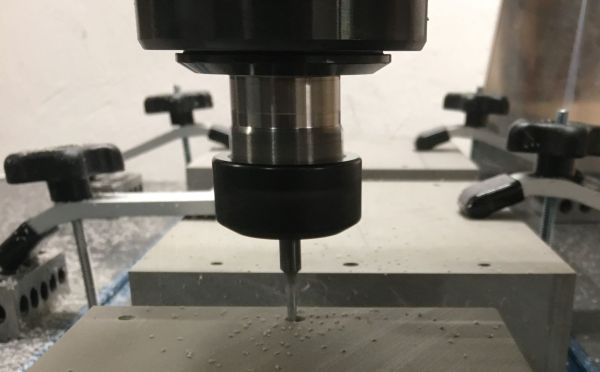

Industrial CNC spindle router for prototype tooling.

Gaging inspection equipment up to 24".

Laser scanning resources available.